All images and information used with permission of Delta Air Lines.

Reverse Engineered Headlamp Clip

SolidWorks

3D Scanning

DesignX

Reverse Engineering

Situation

The original headlamp clips used in the maintenance shops, which hold the headlamp at the desired angle, easily fractures when they are dropped in the shop, and replacement involves purchasing an entire new headlamp for $40.

Streamlight headlamp used in the maintenance shop.

Workflow

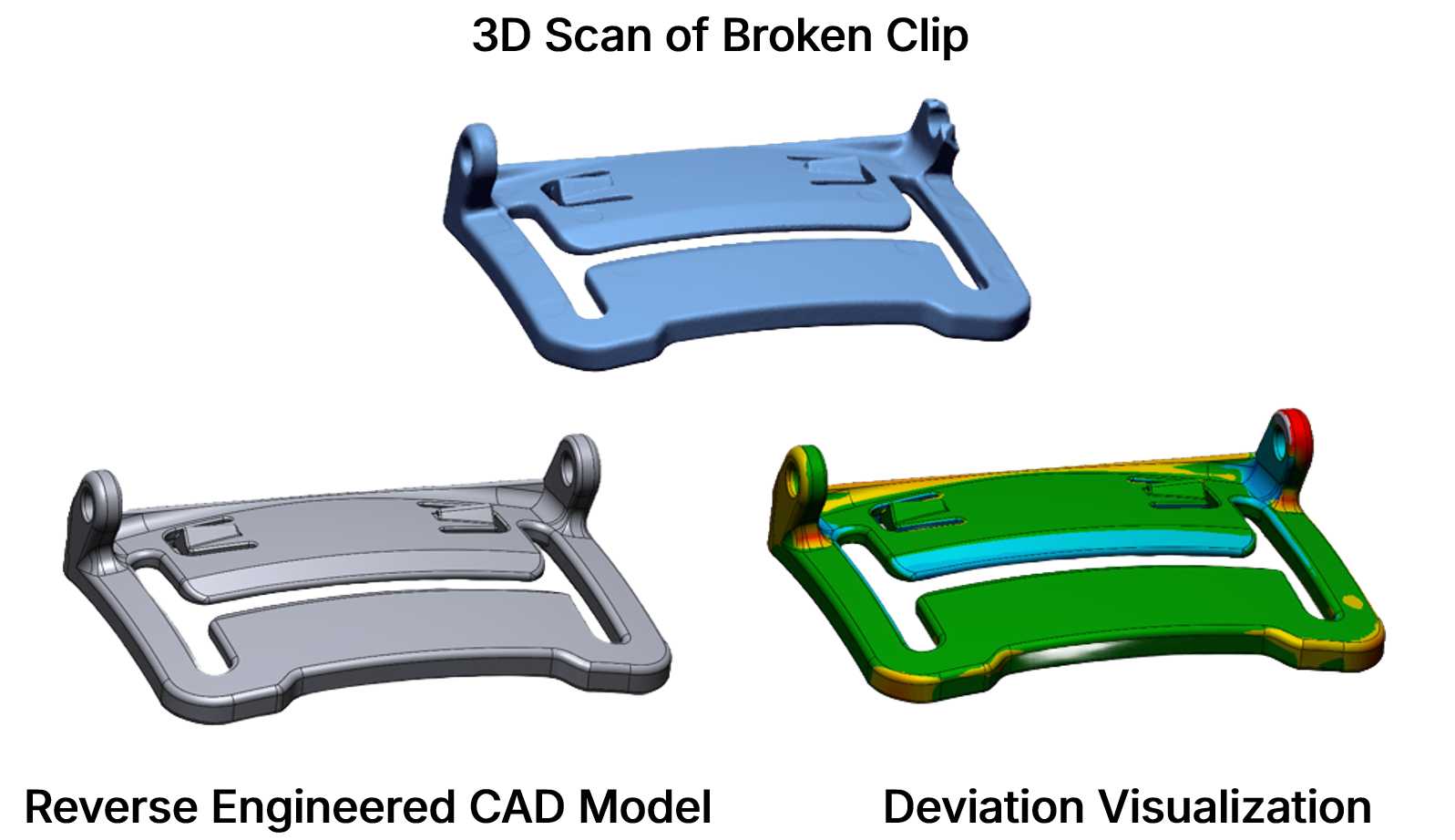

- With a Keyence 3D scanner, I took three different scans at different angles and stitched them together in the scanning software to get an STL from the point cloud data.

- In DesignX, I used the STL mesh geometry to extract features and create an editable solid CAD model matching the original part as closely as possible.

- Throughout the CAD modeling process, I used the deviation visualization to compare the geometry of the model to the 3D scan.

Keyance 3D scan, DesignX CAD model, and deviation visualization of the headlamp clip..

Results

The reverse engineered headlamp clip, made with a tough and durable material called TPU 74D, costs $0.90 in material to produce. 30 replacement clips were printed, saving the shop about $1200.