All images and information used with permission of Delta Air Lines.

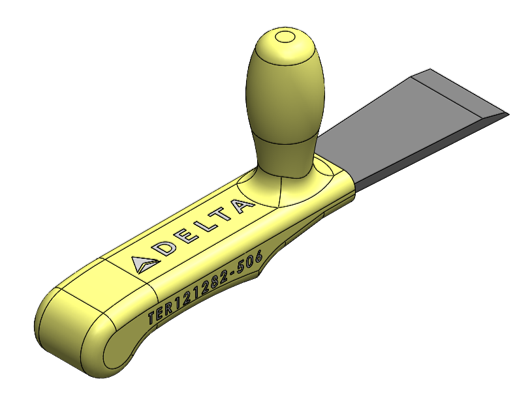

Ergonomic Scraper Handle for Aircraft Maintenance

Situation

AMTs are getting cuts and hand/wrist injuries from using the disposable scrapers (shown below) for hours at a time when removing adhesives, sealants, and other substances from aircraft and engine parts. The manufacturer makes a handle for some of their disposable scraper models, but it costs $21 and is not designed for optimal user comfort and leverage.

Disposable scrapers (top) and compatible handles (bottom) from Jus-N-Tyme.

Workflow

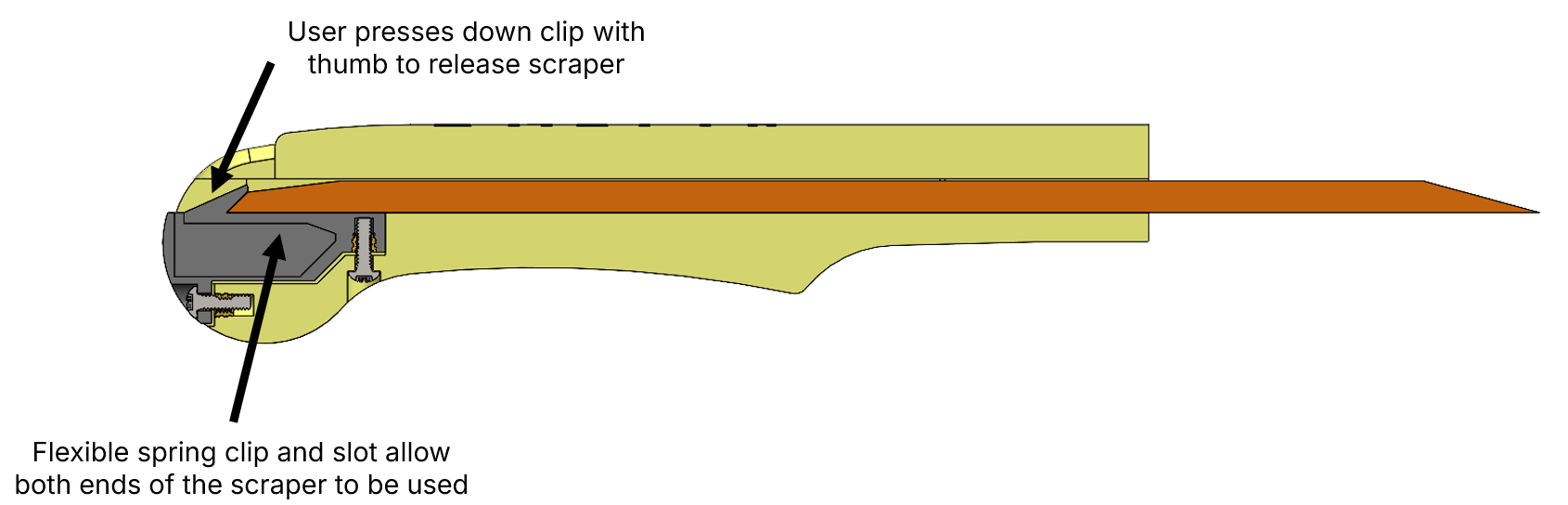

- Using feedback from AMTs across various shops, I iteratively designed a grip geometry that accommodates various hand sizes, grip preferences, and maintenance tasks.

- I designed versions of the handles to be injection molded with feedback from injection molding companies to compare costs between outsourced production and in-house additive manufacturing.

- I used Design for Additive Manufacturing (DFAM) to choose print orientations, parameters, and feature geometries that would minimize post-processing, maximize strength, and ensure consistent insertion of scrapers.

Progress

The five-configuration kit for three different scrapers is being manufactured for all 6000+ AMTs using three dedicated 3D printers purchased by Delta Air Lines for $12,000.

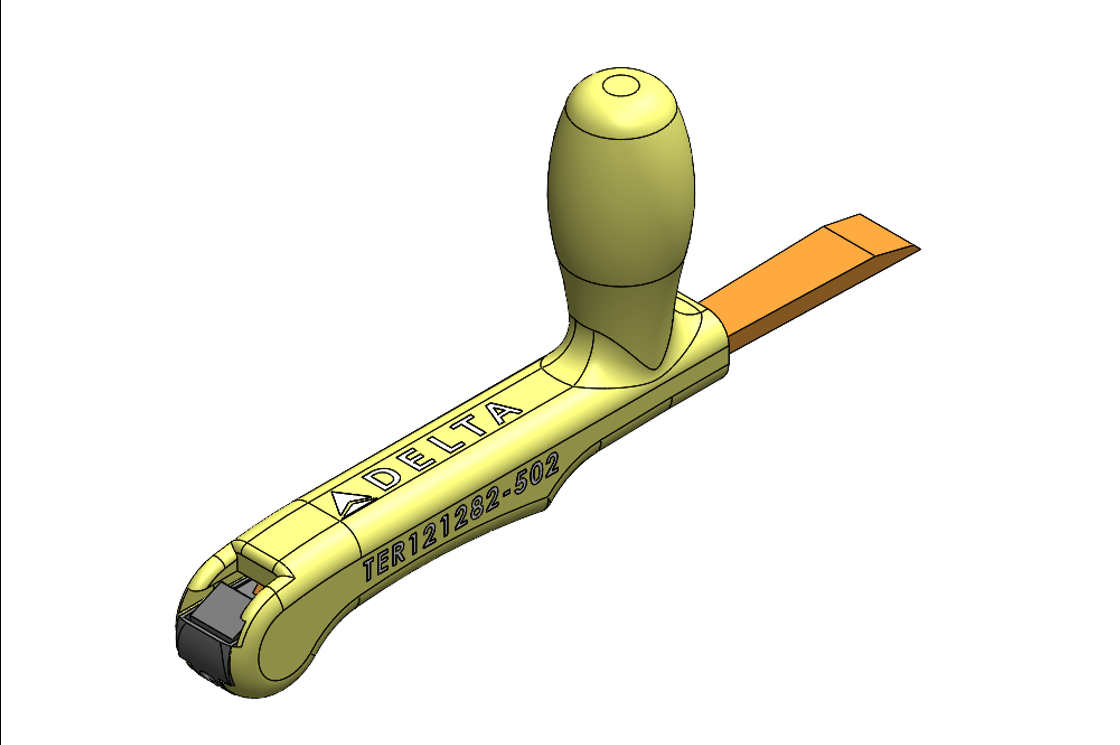

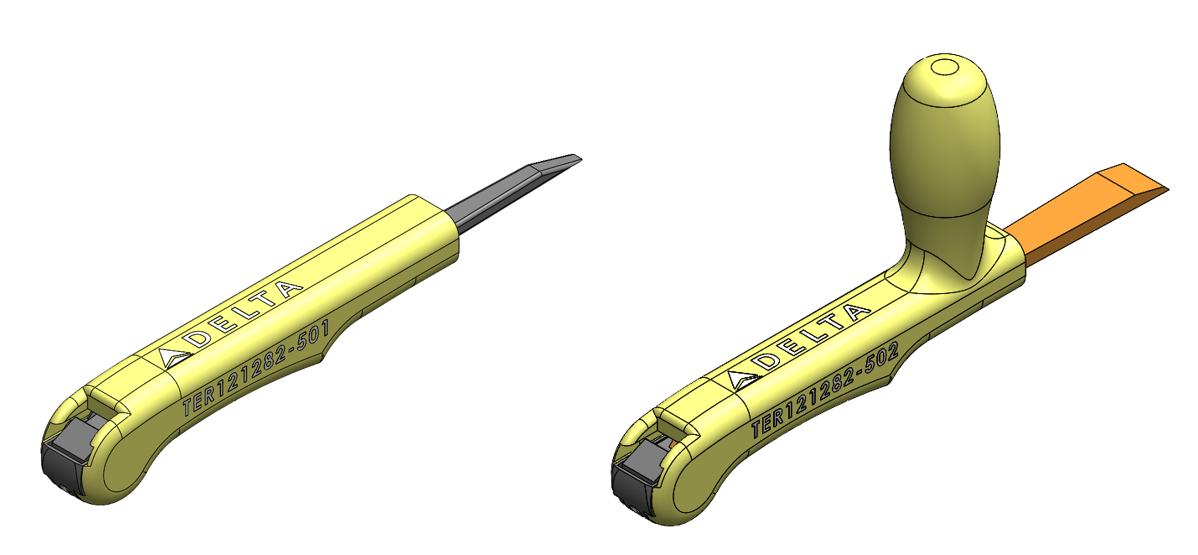

Handles with and without a vertical grip for the thin orange and black disposable scrapers.

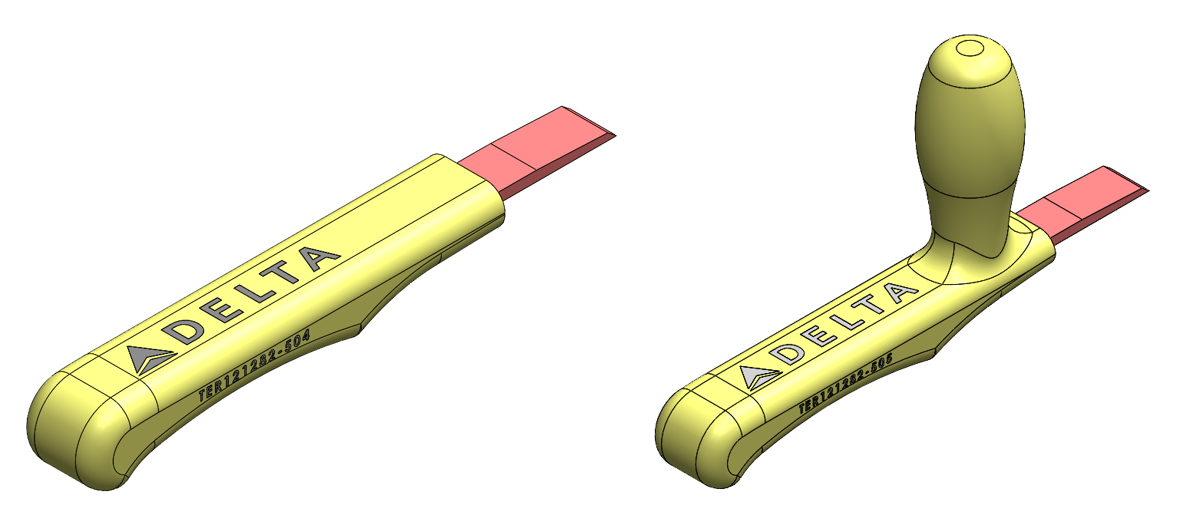

Handles with and without a vertical grip for the thin red disposable scrapers.

Handle with a vertical grip for the thick black disposable scrapers.