All images and information used with permission of Delta Air Lines.

A220 Nose Landing Gear Repack Fixture

SolidWorks

Weldments

SolidWorks Drawings

Design for Manufacturing and Assembly

Situation

Aircraft maintenance technicians (AMTs) at MSP built a fixture for installing and removing the sliding tube of the A220 nose landing gear, and documentation was needed for other maintenance stations to produce the fixture.

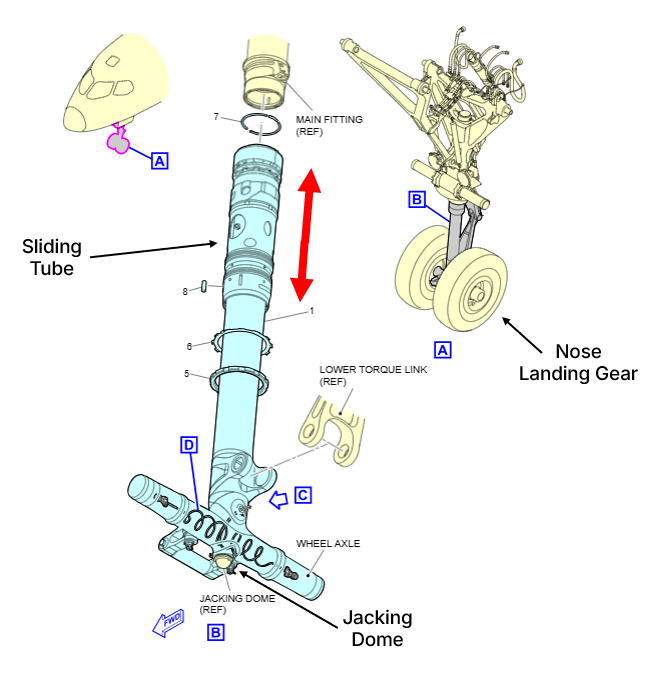

Diagram of the sliding tube within the nose landing gear (left) and the existing A220 nose landing gear repack fixture (right).

Workflow

- Using the Weldment tools in SolidWorks, I translated the existing fixture (shown above) into a CAD model.

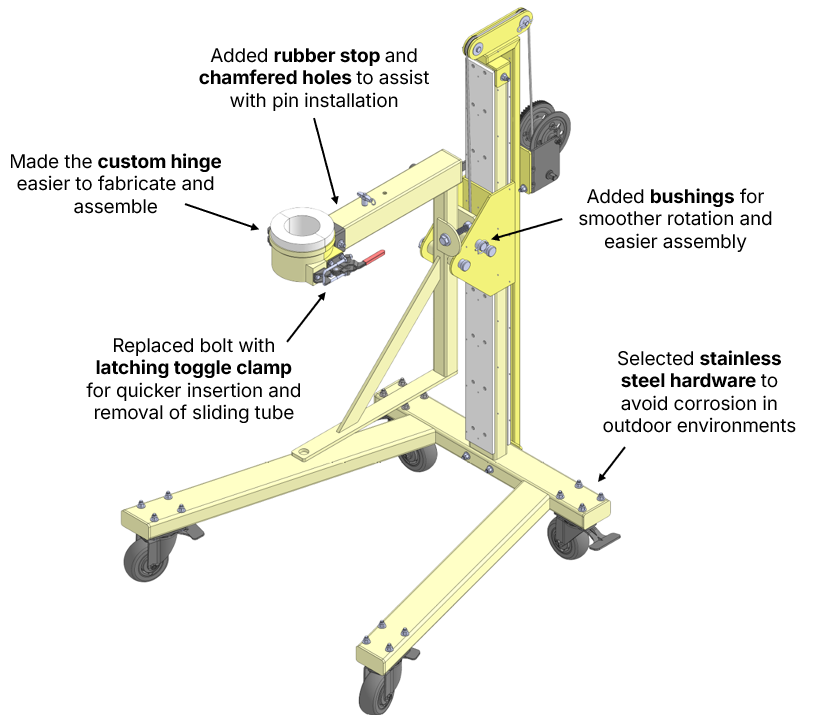

- I modified aspects of the design to improve its operation and fabrication, including adding a latching toggle clamp for the retaining ring that holds the sliding tube and redesigning the hinge to be made with simpler machining operations.

- With the final CAD model, I created a manufacturing drawing package and a bill of materials to allow A220 Nose Landing Gear Repack Fixtures to be produced at other maintenance stations.

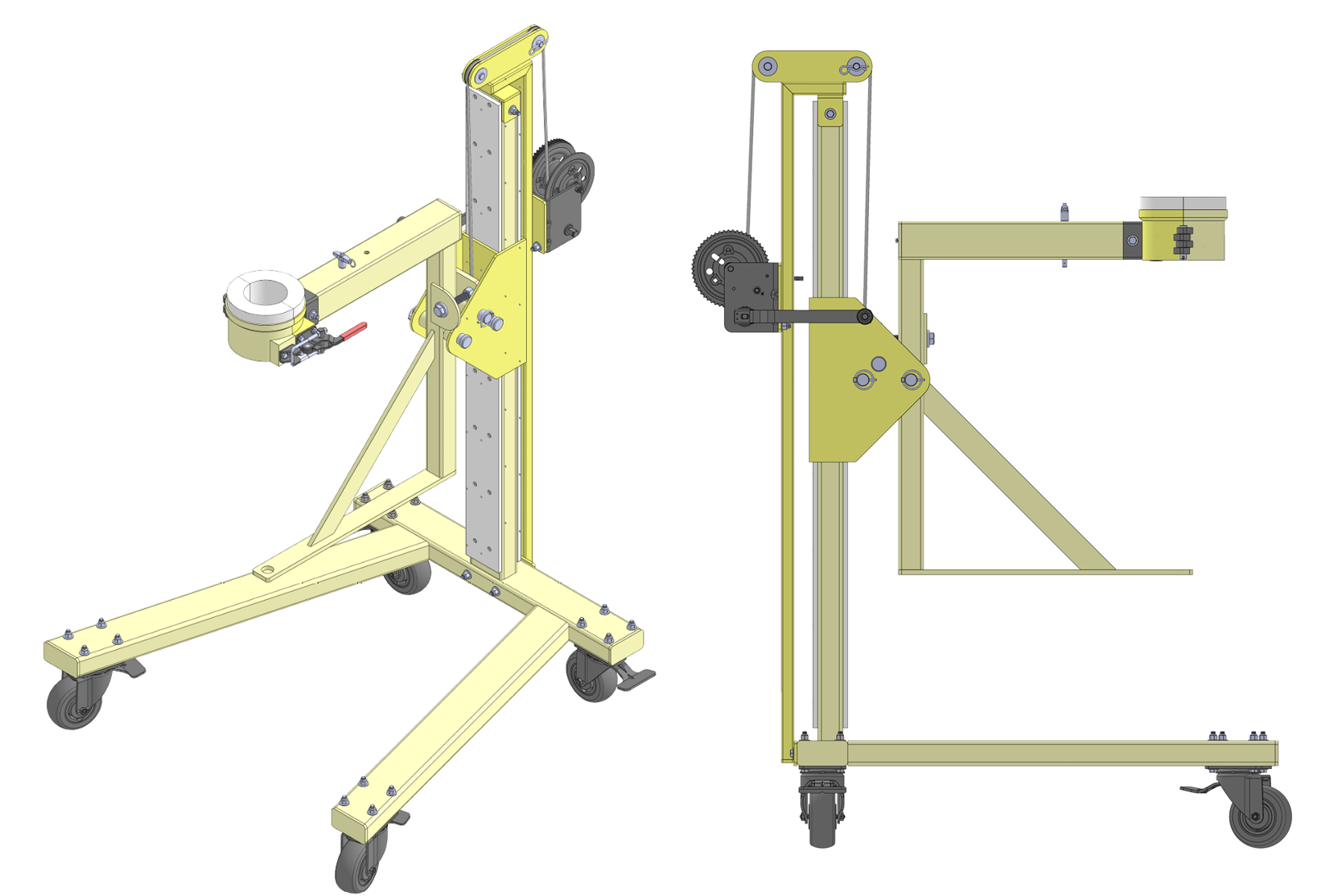

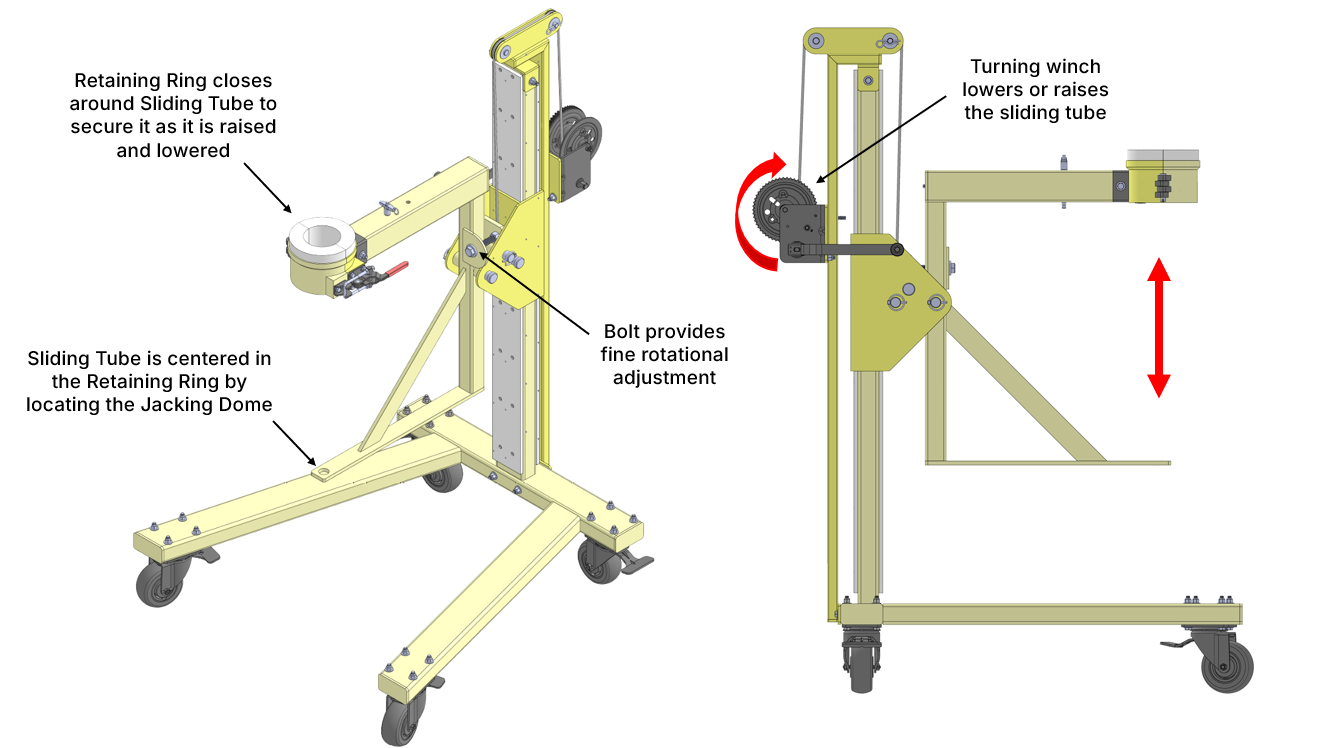

CAD assembly of the improved A220 nose landing gear repack fixture, showing how it is used to carefully install and remove the sliding tube.

Hardware and design improvements made to improve the tool's operation, fabrication, and lifetime.