3D Printed Saxophone Keys for Users with Long Fingers

Situation

The alto saxophone has a fixed key configuration, making it difficult for users with long or uniquely shaped fingers from playing comfortably and at their full potential. Custom brass keys are expensive and typically accessible for only professional musicians.

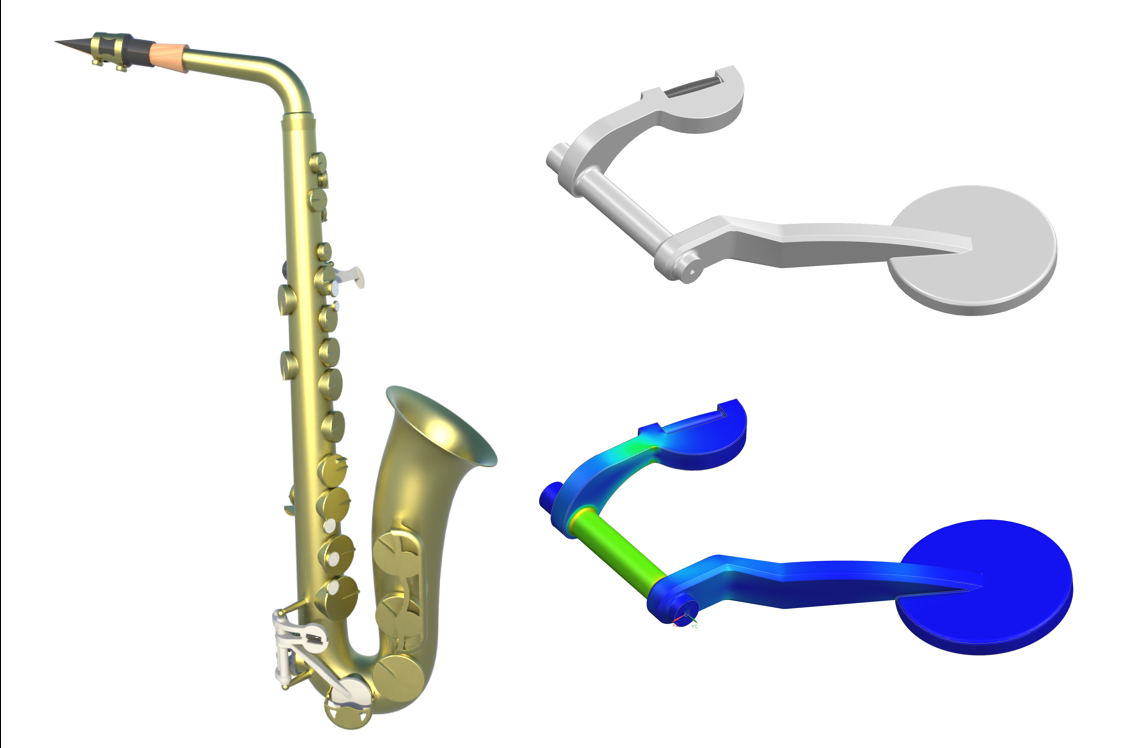

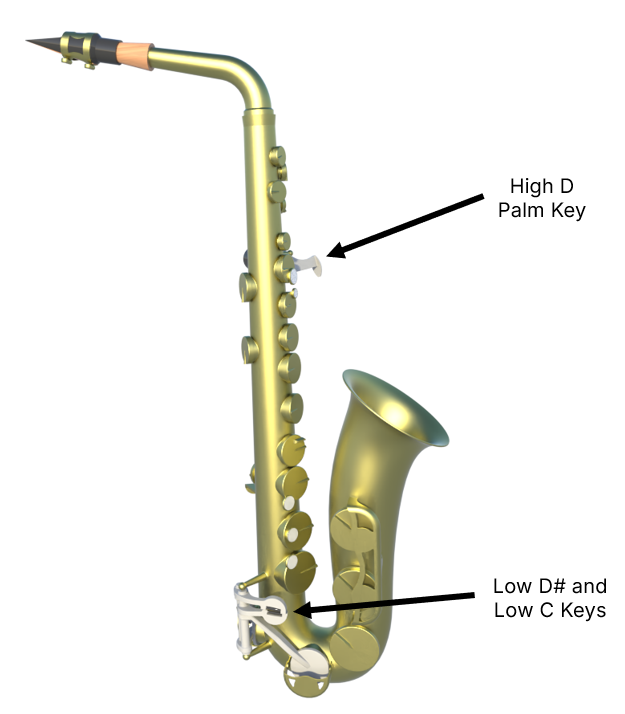

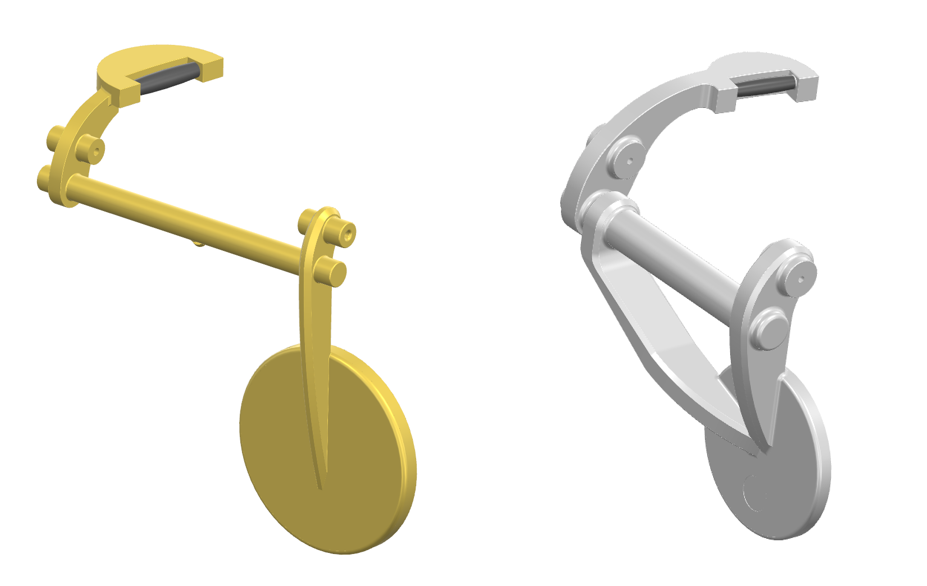

CAD assembly of the alto saxophone designed and rendered in Siemens NX.

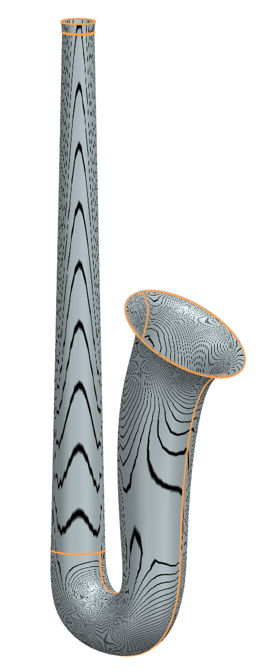

Smooth, continuous reflection lines indicate G2 surface continuity.

Workflow

- With NX’s surface modeling operations and reflection analysis, I modeled the alto saxophone body with G2 surface continuity.

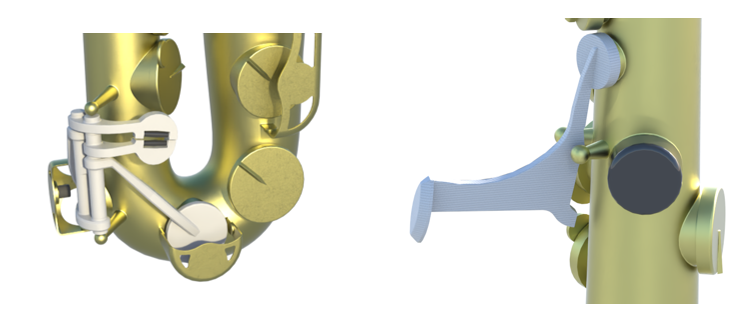

- For the three keys that long-fingered users struggle to use the most (Low D#, Low C, and High D), I modelled the original brass key geometries and mechanisms before creating elongated versions that would be more comfortable to use.

- Using structural Nastran Simulations in NX, I analyzed the stress distribution within the original brass keys and iteratively adjusted the geometry of the elongated keys to resist yielding and excessive deformation when manufactured in nylon using selective laser sintering (SLS) 3D printing.

Models of the extended, 3D-printed Low D#/Low C keys (left) and High D Palm Key (right) integrated with the existing key mechanisms on the alto saxophone.

Simulation of the Low C Key

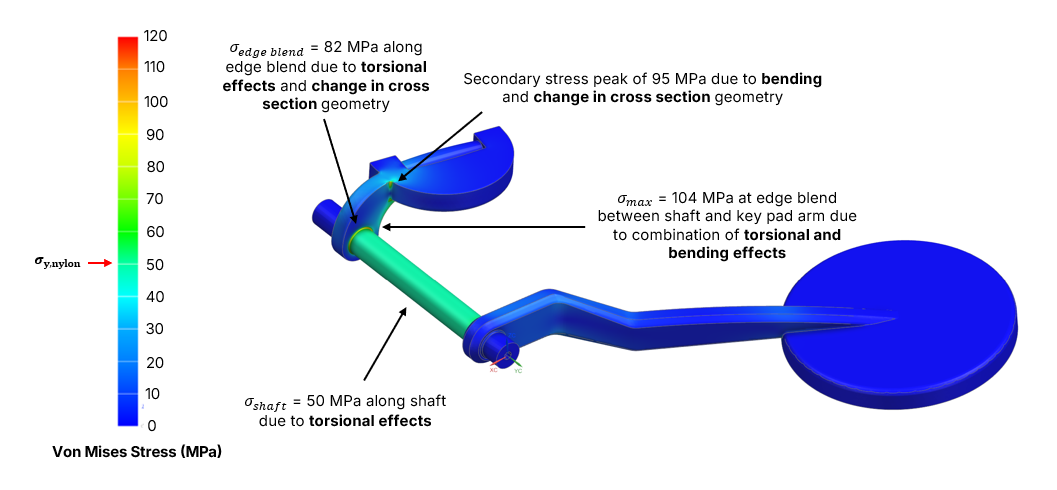

First, a structural simulation of the original brass Low C key was conducted to find the stress concentrations developed during actuation.

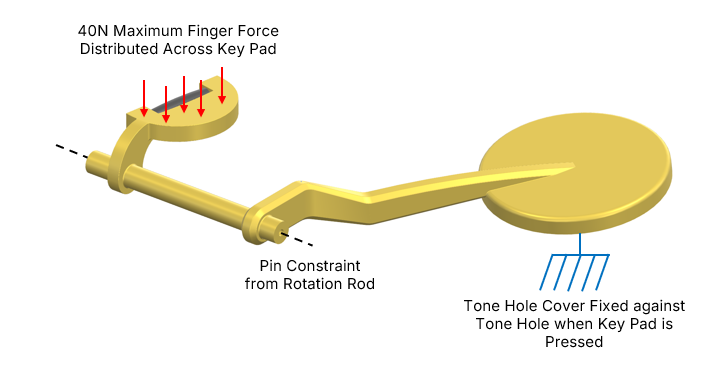

Loads and constraints applied to the Low C Key across all simualtions.

The simulation indicates that with the original geometry of the key, yielding will occur if it is made of nylon instead of brass since the maximum Von Mises stress is greater than the yield strength of nylon.

Nastran NX simulation of the original brass Low C key.

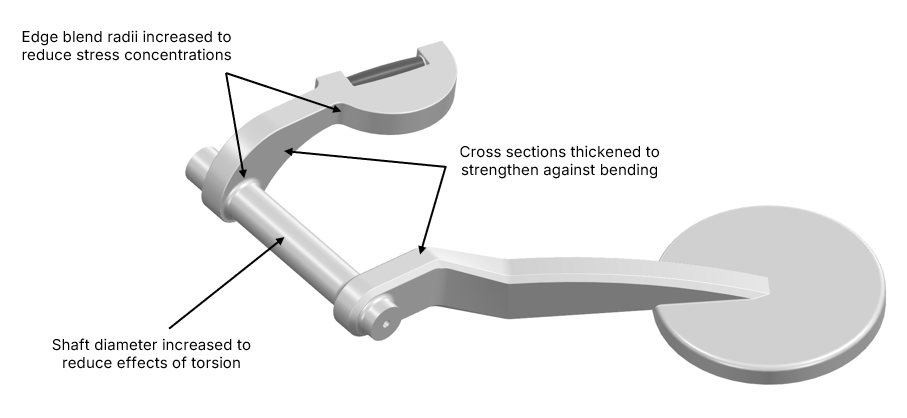

To reduce the Von Mises stresses safely below the yield strength of nylon, the following geometry changes were made:

CAD model of the first iteration of the extended nylon Low C Key.

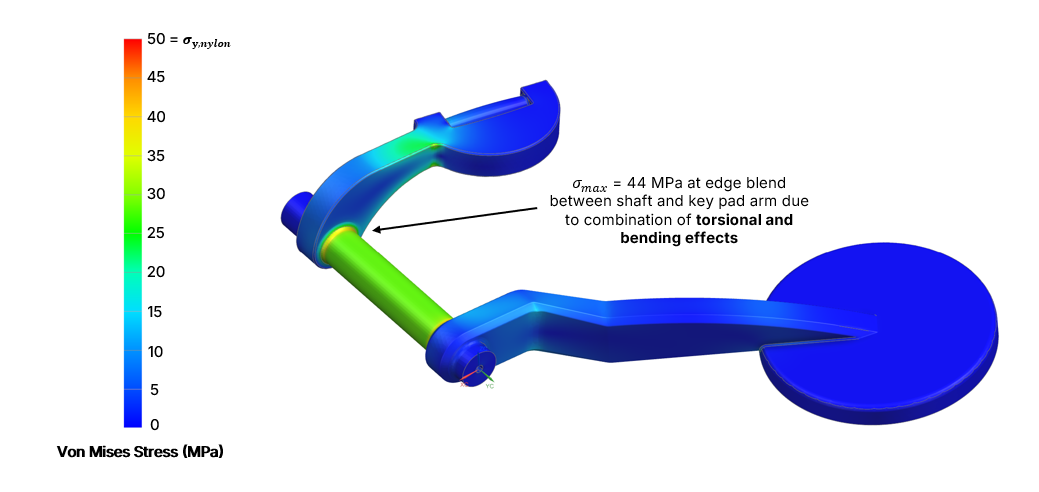

While these changes reduce the maximum Von Mises stress below the yield strength, the displacement at the end of the key, 6.5 mm, will cause interference with other components and inhibit smooth playing.

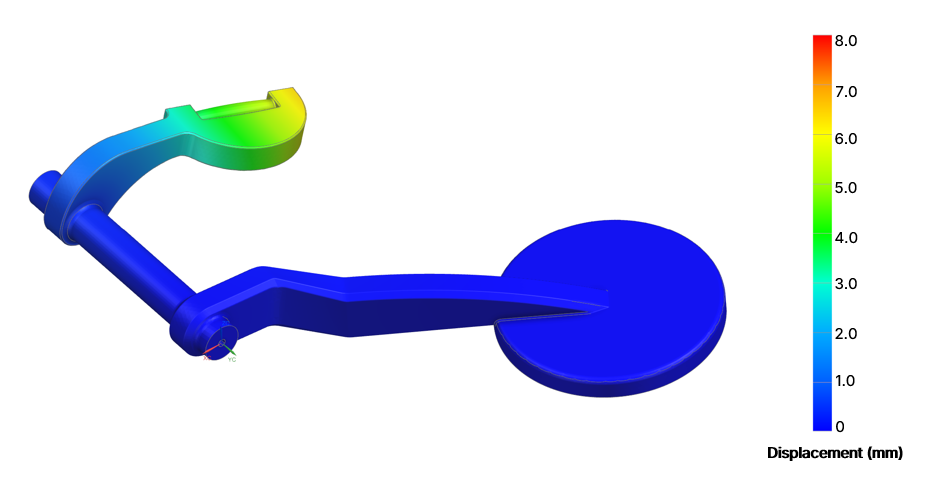

Nastran NX simulations of the first iteration of the extended nylon Low C key.

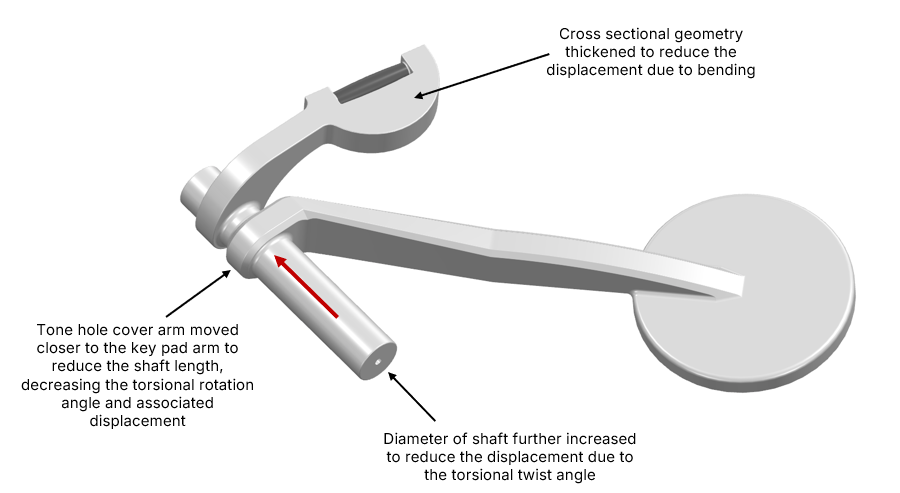

In response, futher geometry changes were made, as shown below:

CAD model of the final iteration of the extended nylon Low C Key.

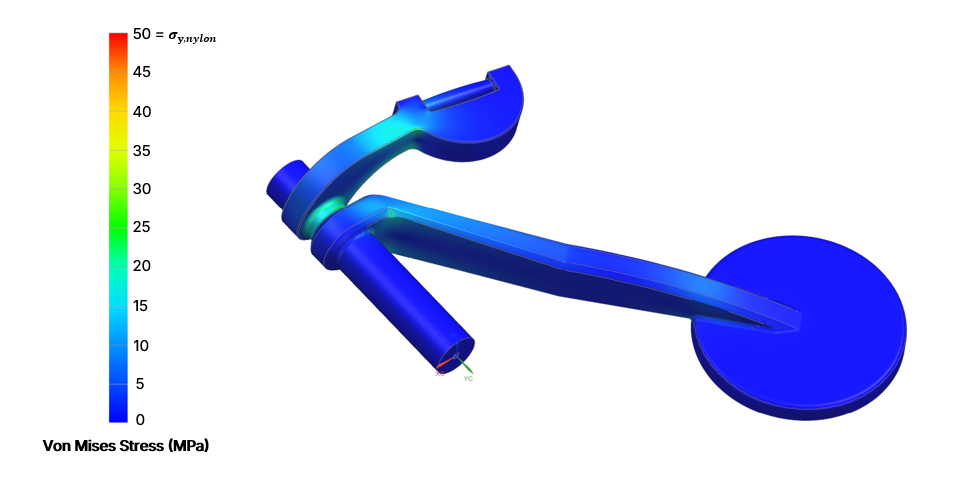

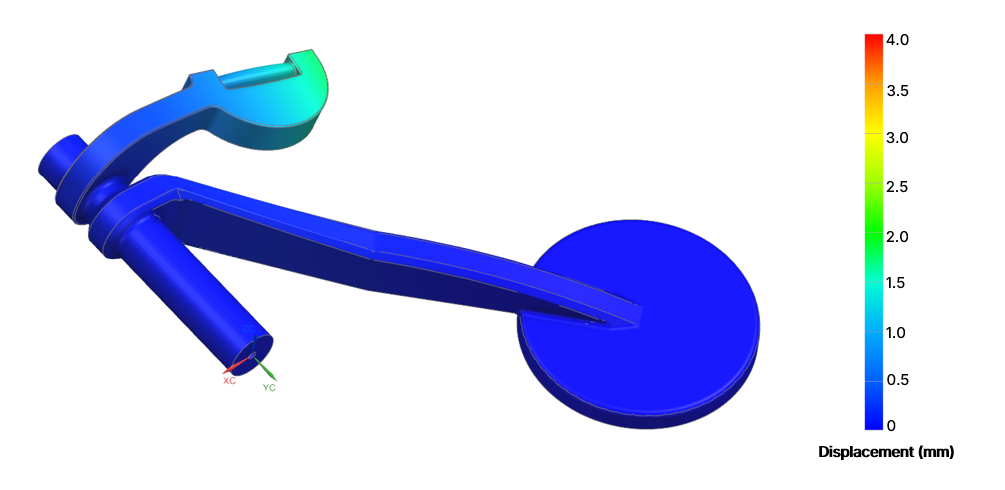

Simulation of the final Low C Key indicates a maximum Von Mises stress of 27 MPa and safety factor against yielding of about 1.85 when the key is subjected to the average maximum force of the pinky finger. The 1.75 mm maximum displacement is small enough to avoid interference with other components or inhibit smooth playing.

Nastran NX simulations of the final iteration of the extended nylon Low C key, validating its design against yielding and excessive displacement.

The results of this iterative simulation and design cycle guided the geometric modifications made to the other keys.

Models of the original, brass Low D# Key (left), and the extended, 3D-printed version designed to resist yielding during playing (right).

Progress

The three elongated keys resist yielding and interference with other keys, proving that 3D printing provides an affordable solution for custom instrument keys.

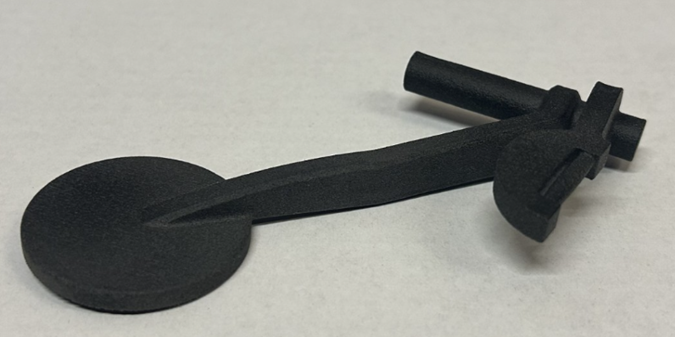

Low C (top), Low D# (center), and High D Palm (bottom) keys 3D-printed in nylon on a Formlabs Fuse 1 selective laser sintering (SLS) 3D printer.