All images and information used with permission of Delta Air Lines.

Aircraft Engine Part Masking

SolidWorks

Design for Additive Manufacturing

Situation

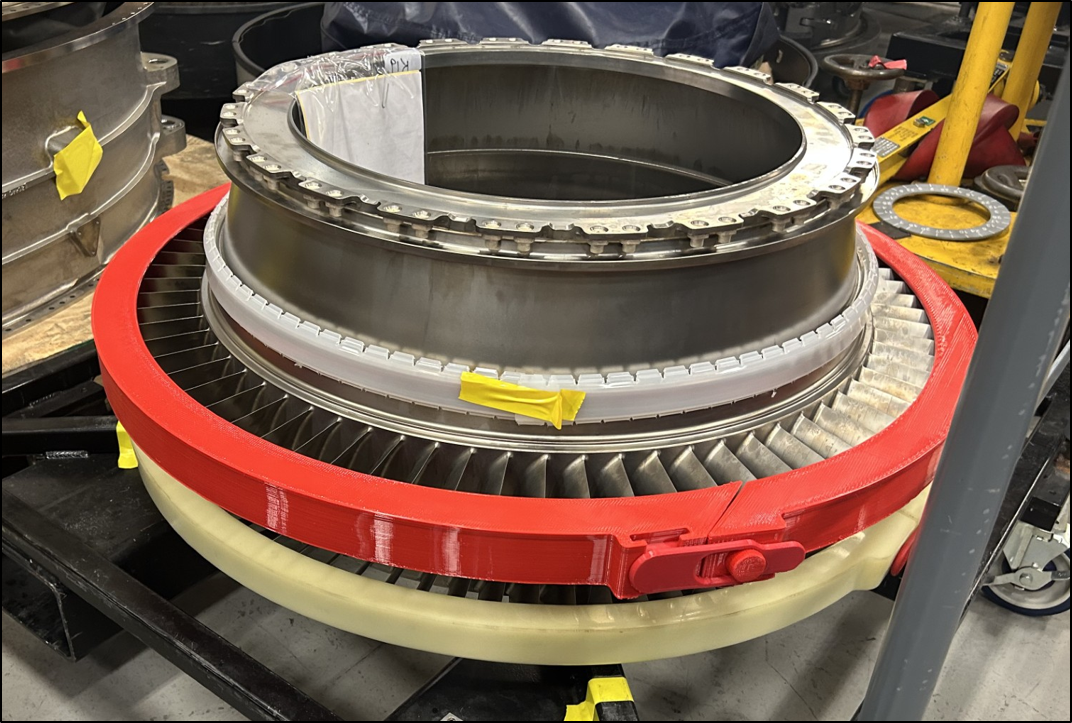

The covers from Rolls Royce (white in the image above) that protect the 2nd and 3rd Stage Blades on the BR715 Low-Pressure Compressor cost over $1000 each.

Workflow

- After receiving the Big Rep Pro 2, I worked to optimize print parameters and create a standard operating procedure for large TPU prints.

- I performed tests to optimize the parameters to compensate for shrinkage and print with easily-removed sacrificial support material.

Results

The reverse engineered covers (red in the image above) 3D printed on our Big Rep Pro 2 printer provide the same level of protection for less than $150 in material. Printing four covers saved Delta Air Lines over $3,400 in material costs and significantly reduced lead time compared to purchased OEM protective covers.