All images and information used with permission of Delta Air Lines.

Aircraft Engine Part Masking

Situation

To protect the features of engine parts that cannot be shot peened or blasted, aircraft maintenance technicians (AMTs) manually cover them with blast tape. This precise and time-consuming process often leads to expensive part rework due to taping inconsistencies or tape blowing off during blasting.

Workflow

- Using scanned models of the parts, I designed part masks to tightly fit around the features to be protected, accounting for the shrinkage of TPU during printing.

- I implemented Design for Additive Manufacturing (DFMA) practices to design parts without the need for support material.

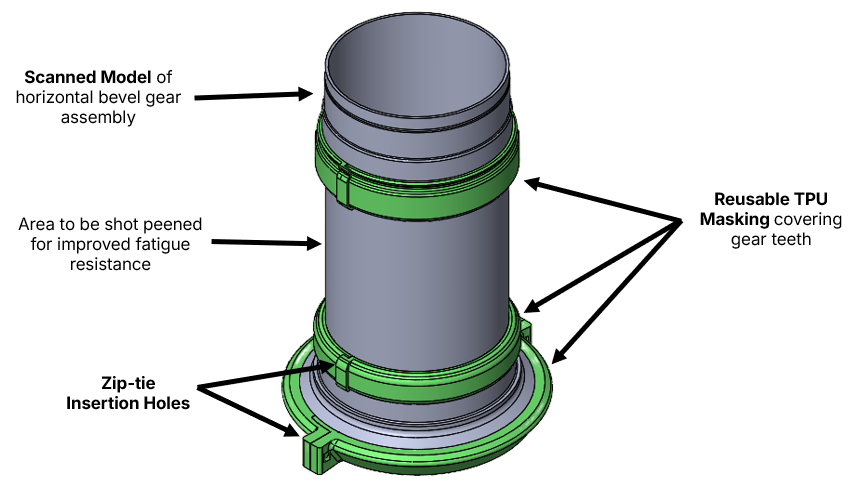

Example 1: CF6 Horizontal Bevel Gear

These flexible TPU parts cover the gear teeth on the horizontal bevel gear of the inlet gearbox assembly of the CF6-80C2B6 aircraft engine to prevent damage during shot peening. Before, $6-8 of single-use blast tape is used per application, which takes about 15 minutes. With this $42 set of TPU masks, application takes less than 5 minutes, and they can be reused for hundreds of parts.

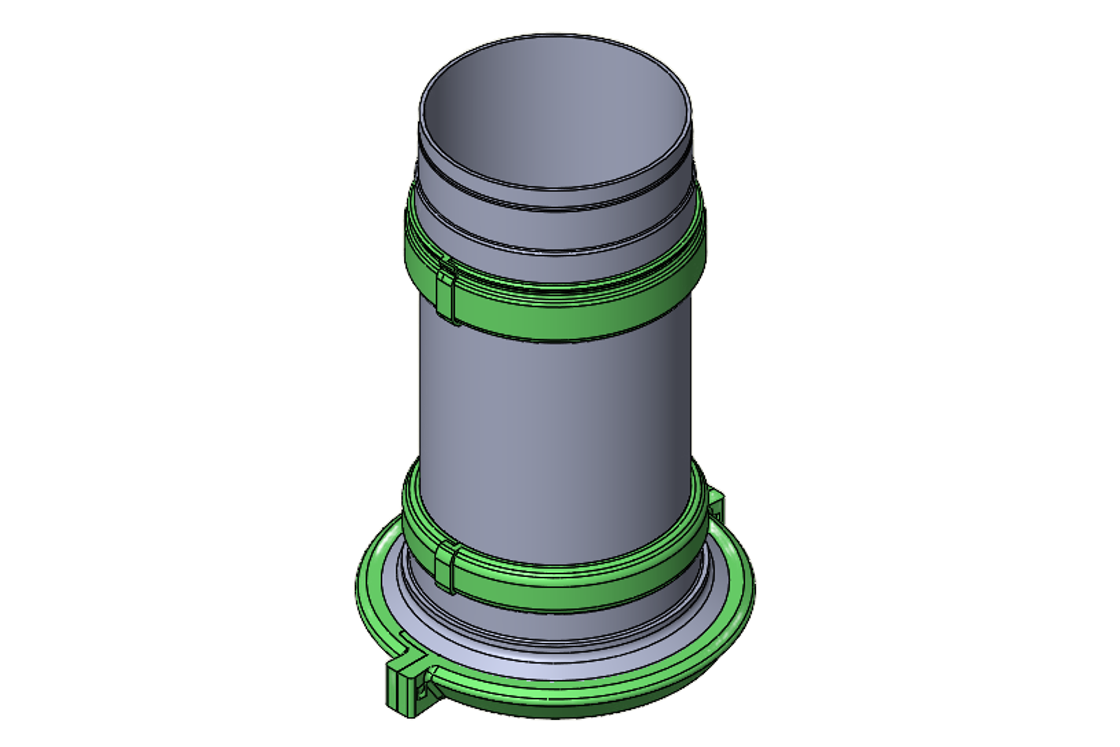

CAD model of the horizontal bevel gear and its three additively manufactured masks for shot peening.

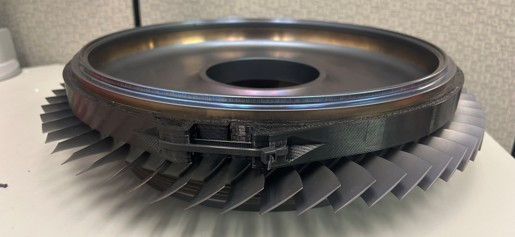

Example 2: PW1500 HPC Blisk

During shot peening, this mask covers the rubstrip of the PW1500 aircraft engine’s high pressure compressor 4th stage blisk, crucial for maintaining the air seal between it and the adjacent stage’s stator vanes for maximum engine efficiency.

Additively manufactured TPU mask installed on the Stage 4 Blisk.